Product Mame

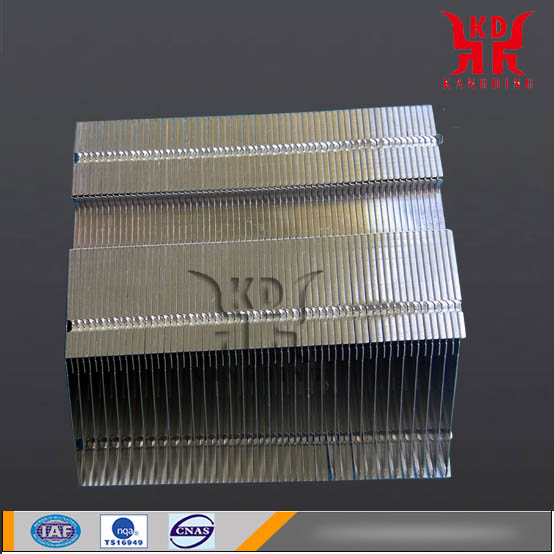

Metal Parts processing is the use of raw materials (stainless steel, copper materials, aluminum materials, iron materials, iron materials, aluminum alloys.....), machining of customer drawings or samples using CNC, lathes, milling machines, drilling machines, polishing machines, etc. Become a variety of parts, such as: screws, motor shaft, model car parts, fishing accessories, speaker enclosures, mobile power enclosures.

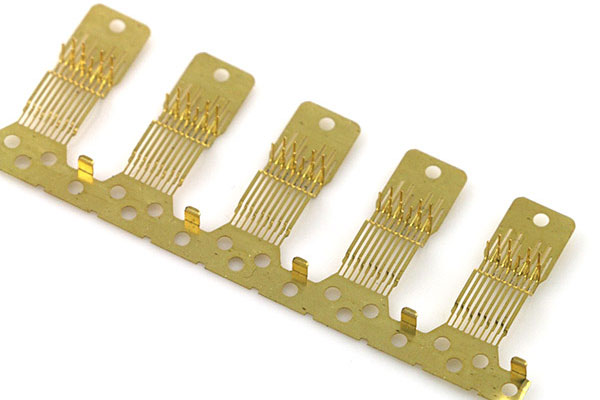

The main processing methods of metal parts are: machining, stamping, precision casting, powder metallurgy, metal injection molding. Metal Products, Metal Processing, Metal Stamping, Metal Fabrication, Metal Accessories, Metal Parts

Metal fittings refers to the collective name of metal fittings and certain gadgets that are installed on buildings or furniture, such as nails, screws, iron wires, locks, hinges, bolts, springs, etc. metal refers to five metal materials: gold, silver, copper, iron, and tin. metal is the mother of industry; the foundation of national defense.

With a wide variety of products and specifications, metal fittings play an irreplaceable role in home decoration. Choosing good metal accessories can make many decorative materials safer and more convenient to use. At present, there are more than ten types of metal products in the market.

Classification

There are a wide variety of metal products with different specifications, but metal products also play an irreplaceable role in home decoration. Choosing good metal accessories can make many decorative materials safer and more convenient to use. Currently materials market actually operated metal products a total of more than 10 categories, hundreds of products.

Mechanical hardware: fasteners, rolling bearings, belts and chains, lubricating parts, keys and splines, welding equipment, lifting equipment, etc.

Construction hardware: building profiles and structural parts, building doors and windows and their hardware accessories, nails and nets, plumbing equipment, fire-fighting equipment and automatic fire alarm devices.

Electrical hardware: general-purpose wire and cable, buttons and switches, relay contactors, electromagnetic starters and electromagnets, fuses, circuit breakers and leakage protection devices, control transformers and signal lights, AC motors, electrical instruments and so on.

Hardware tools: hand tools, civil tools, plumbing tools, hand tools for decorative works, electric tools, cutting tools, measuring tools, power tools, pneumatic tools, garden tools, etc.

Hardware materials: steel materials, metal materials, non-metallic materials, etc.

Hardware machinery and equipment: Machine tools, pumps, valves, food machinery, instrumentation, and packaging materials manufacturing.

Metal products: alloys, metal processing materials, ordinary steel, stainless steel, metal wire, rope, metal mesh, scrap metal.

General Parts: fasteners, bearings, springs, seals, rigging, gears, molds, abrasives.

Metal tools: household tools, grinding, hydraulics, lifting, measuring, saws, hammers, screwdrivers, wrenches, electric, hand tools.

Construction hardware: pneumatics, doors and windows, fittings, kitchens, lamps, sanitary ware, locks, construction, building materials, and coatings.

Electronic and electrical: low-voltage electrical appliances, instrumentation, chargers, motors, connectors, anti-static, cables, insulation materials, electronic materials.

Technology

Hardware Machining can also be called metalworking. Turning, milling, planing, grinding, boring, etc., modern processing increases the electrical discharge machining. In addition, die casting, forging, etc. are also commonly used processing methods. If purely involved in sheet metal, then milling, grinding, wire cutting (discharging as well as heat treatment) and heat treatment are commonly used.

Metal processing can be divided into: automatic lathe processing, CNC machining, CNC lathe processing, five-axis lathe processing, can be roughly divided into: metal surface processing, metal forming two categories.

Rapid prototype making examples

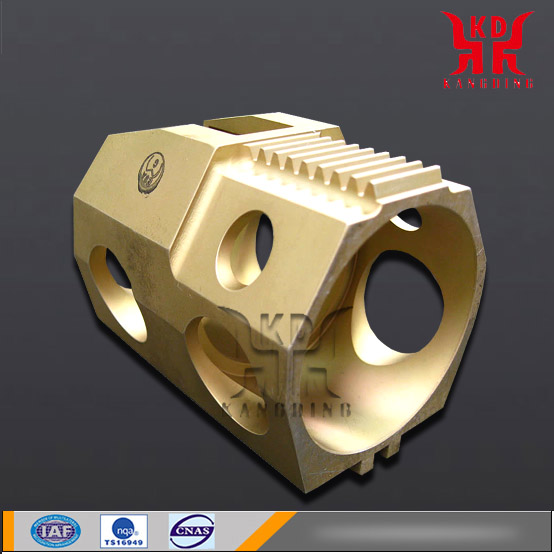

In general, rapid prototyping is the use of cnc processing are produced, the following by more than 10 years experience Kang Ding model engineers, to introduce the process of metal prototyping: design drawings, programming, cnc processing, grinding, assembly, Fuel injection, oxidation, laser engraving and other processes.

Design drawings: Prototype drawings are generally made using AUTOCAD. Professional designers are required. Under normal circumstances, the format of the prototype is mainly .IGS/.STP/.STL/.PRT/.X-T.

Cnc processing: the execution of program commands, and more precisely should be like this - tungsten steel knife in accordance with the path set by the program, the engraving on the aluminum alloy back and forth, the excess part removed, so as to get a prototype product.

Grinding: After a part is processed by a CNC machine tool, its surface will have a lot of burrs and marks. These machines cannot be completed, so this will require manual manual handling of these issues. It is usually polished with a polishing paste or sanded. When polishing, you should notice the problem. The first step is to use rough sandpaper for roughing and grinding. Remove the coarse burr on the surface and then fine-grained.

Surface coating: Spray a layer of paint on the surface of the prototype to make it achieve the same color as the design drawings. In general, we use the ppg coating for fuel injection, bright color, long-lasting, not easy to fall off.

Oxidation: Anodic treatment, oxidation of the surface of aluminum to form a film, so that the product is not easy to scratch.

Laser engraving: Laser engraving is also called laser engraving or laser marking. It is a technique that uses optical principles for surface treatment.

Assembly: It is to assemble the various parts of the aluminum alloy prototype. After processing, it is the data detection of the assembly problem.

Standard

After many years of development, Kangding has set clear standards for the quality inspection of metal parts and standardized inspection actions so that the standards for inspection and determination can be consistent:

Measuring tools: vernier caliper with accuracy of 0.01mm, tape measure or steel ruler with accuracy of 0.1mm, feeler gauge with accuracy of 0.01mm, plug gauge with accuracy of 0.01mm, Colorimeter, height gauge with accuracy of 0.01mm, 0.002mm crossbar meter, Thick gauge, Aperture gauge, Teeth regulations, Baige knife, 3M adhesive tape, Salt spray test box, Oven, constant temperature and humidity box.

1) Metal burr: Due to mechanical punching or cutting, it is not handled well. Causes metal burrs on the edge or parting surface of the workpiece.

2) Scratches: Scratches and cuts on the surface of the product due to improper protection during processing, packaging, and transportation.

3) Cutting missing: Due to the positioning of the product during the processing or improper fixation of the device, the edges of the product are cut unevenly.

4) Deformation: Plane deformation of the product caused by improper adjustment of the processing equipment or material due to internal stress.

5) Oxidation: Due to the lack of corresponding rust prevention after processing of the product, rust spots appear on the surface of the product.

6) Size deviation: due to the inaccuracy of the processing equipment, the product size deviation exceeds the design allowable level.

7) The “R angle” is too large/small: The product has insufficient accuracy due to bending or stamping equipment, resulting in excessively large/small curvature at the bend.

8) Surface dents: Due to poor heat treatment of the material or rusting of the material, its internal impurities cause dents to form on the metal surface.

9) Round not enough: Sharp edges are formed on the edge of the product due to cutting or punching, and are not processed into arcs, which can easily lead to cutting.

10) Heterochromatic dots: Points appearing on the surface of the product that are different from the surrounding color.

11) Cracking: Cracks or small cracking of the product due to machining damage.

12) pitting: fine particles have adhered to the coating surface.

13) Stack paint: Partial paint accumulation on the surface of the painted part.

14) Shadow: The surface of the painted part appears darker than the surrounding area.

15) exposed background: spray paint local phenomenon pieces too thin to expose the substrate color.

16) Fisheye: Indentations or small pits appear on the surface of the painted part due to the wrong speed of solvent evaporation.

17) Flying oil: beyond the specified spray area.

18) Peel off: The coating surface is peeled off.

19) Color difference: The color of the product surface is different from the color of the standard sample.

20) Handprint: fingerprints appear on the surface of the product.

21) Hard Scratches: Scratches on the surface of the product due to friction of the hard object (marked with nails).

22) Soft Scratch: There is no significant depth of scratch (no feel, but the naked eye can clearly see).

Galvanized, nickel-plated, chrome-plated, gold-plated, silver-plated, blackened, oxidized, electropolished, pickled, phosphatized, electrophoretically, painted, spray-coated, porcelain-coated, polished, Brushed polishing, ground, shot-peened, cast Pills, vibration grinding, Plastic covered.

1, Spray paint processing:

The current hardware factory in the production of large pieces of hardware products are used when the paint processing, through the paint processing hardware to avoid rust, such as: daily necessities, electrical enclosures, handicrafts and so on.

2, Electroplating:

electroplating is also the most common processing technology of metal processing, through the modern technology of the hardware surface plating, to ensure that the product does not oxidize and rust during prolonged use, electroplating processing is common: screws, stampings, battery pieces, car parts, small jewelry and so on.

3, Surface polishing:

Polishing is to make the product maintain the appearance of a bright appearance, so the precision metal processing technology used in our daily use is very wide, especially in some easy to pilling and burr products, Polishing is a necessary step.

4, alloy catalytic liquid technology:

The alloy catalytic liquid is suitable for various metal materials and can be catalyzed as long as it can be soaked in the flow. The product can be processed by heating to about 83°C at room temperature. During the processing, the metal is generally immersed in about 15-20 minutes, soaked with clean water, It can be used after dry naturally.

5, Blackening:

Blackening is a common method of chemical surface treatment. The principle is to produce an oxide film on the metal surface to isolate the air and achieve rust prevention.

6, Anodic oxidation

Electrochemical oxidation of metals or alloys. A process in which aluminum and its alloys form an oxide film on an aluminum product (anode) under the influence of an applied current under a corresponding electrolyte and a specific process condition. Anodization is usually anodization of sulfuric acid unless otherwise specified.

In order to overcome the defects in the surface hardness and wear resistance of aluminum alloys, to extend the application range and prolong the service life, the surface treatment technology becomes an indispensable part in the use of aluminum alloys, and the anodizing technology is currently the most widely used and most successful.

Design

Stamping parts design:

1, the design of the stamped parts must meet the product use and technical performance, and can facilitate the assembly and repair.

2, the design of stamping parts must be conducive to improving the utilization of metal materials, reducing the variety of materials and specifications, as much as possible to reduce the material consumption.

3, the design of the stamping parts must be simple in shape, reasonable structure, to facilitate the simplification of the mold structure, simplify the number of processes, and facilitate the organization of mechanized and automated production, in order to improve labor productivity.

CNC machining part design:

1, select part blank material

According to the part process design, the blank selection refers to the determination of the type of blank, the manufacturing method, and the blank size after the allowance is determined.

2,Determine the positioning reference point for complex parts

When selecting the rough reference for processing, the key point to consider is how to ensure that there is enough margin on each machining surface so that the size and position between the non-machined surface and the machining surface meet the requirements of the drawings.Therefore, the rough reference can be selected as the plane of the blank. According to the processing of the concave table and the processing of the hole, the bottom surface of the bottom plate is selected by the positioning reference.

3, the development of part machining process route

The main consideration is how to ensure that there is sufficient headroom on each machined surface. According to the processing of the concave table and the processing of the hole, the positioning reference selects the bottom surface of the upper platen.

To select a CNC machine according to the design requirements of the part:

(1) CNC lathes are suitable for machining cavities in molds with relatively complex shaft shapes or complex curves.

(2) CNC vertical boring mills, milling machines and vertical machining centers are suitable for machining inside and outside cavities of boxes, box covers, plane cams, templates, complex-shaped flat or three-dimensional parts, and dies.

(3) CNC horizontal boring mills, milling machines and horizontal machining centers are suitable for processing various complicated box parts, pump bodies, valve bodies, and housings. Multi-coordinated horizontal machining center can also be used to process a variety of complex curves, surfaces, impellers, molds and so on.